Day Model Example

Table of Contents

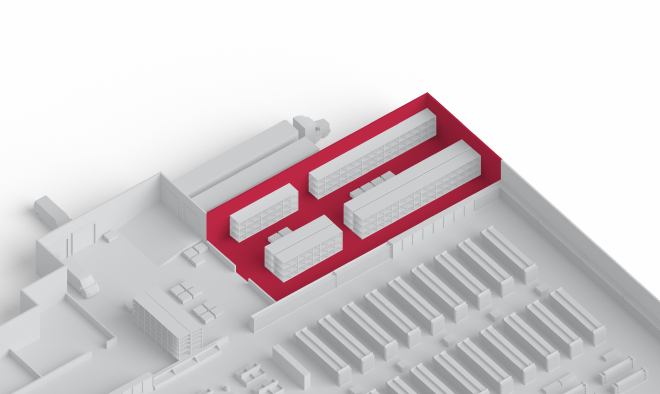

Baseline #

This is an example model built for the business of sub-hour direct-to-consumer grocery delivery.

It assumes that prior to automation:

- customer orders were fulfilled manually

- a single order picking process was used; from standard shelves installed in a dark store

- 3,000 ft2 (279 m2) room was holding enough inventory of 2,000 ambient SKU assortment

- room of 14 ft (4.3 m) clear height to ceiling

Day demand on average was:

- 642 customer orders to be fulfilled

- total of 3,852 order lines and 4,622 items

Daily operations required:

- three shifts with a peak of outbound orders during the second shift

- at peak, 8 associates were fulfilling customer orders to reach the required picking throughput of 720 order lines per hour (LPH)

- maximum picking productivity of a picker was 100 LPH

- a day required 97 labor hours, at $22 total all-in cost of an associate’s labor hour

- a day all-in labor expenses were $2,141

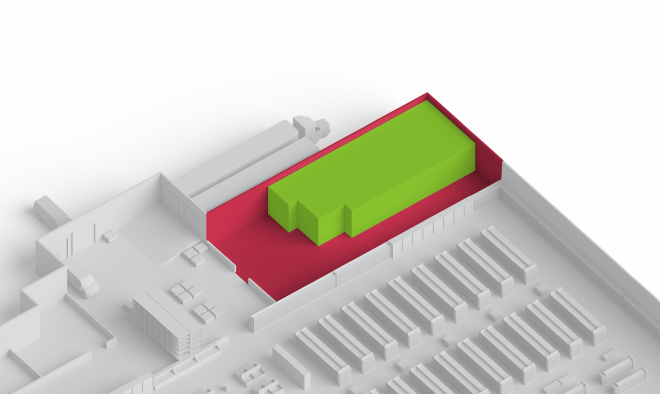

Instock ASRS #

Instock ASRS solution:

- utilizes 1,800 ft2 (167 m2) of floor space in the same room, leaving the remaining 1,200 ft2 (111 m2) for packing, staging, receiving and other support processes

- provides 2,300 plastic bins of storage capacity

- allows expansion of assortment to 3,000 SKUs keeping the same days-on-hands of inventory.

With associates powered by automation:

- total daily cost of automation of $437 is defined by the cost of throughput capacity

- throughput capacity is defined by peak hours (robots are underutilized in non-peak hours)

- gain in picker’s productivity is 6x, and covering peak hours requires only two associates

- shifts are adjusted: one shift of two associates and two shifts of a single associate

Efficiency gains #

Compared to the baseline, daily efficiency from Instock as-as-service solution is $1,073 (or 50% of baseline labor costs) plus an increased assortment from 2,000 to 3,000 SKUs.

| Baseline | InstockASRS | |

|---|---|---|

| Max throughput per single operator | 100 LPH | 600 LPH |

| Labor | 97 h | 29 h |

| Labor cost | $2,141 | $631 |

| Cost of automation | $0 | $437 |

| SKU portfolio | 2,000 | 3,000 |

Besides obvious economic advantages, the automation use case brings improved picking accuracy, associates satisfaction, inventory transparency, and green energy efficiency.